We look forward to hearing from you!

Write to us or give us a call. We are always happy to help.

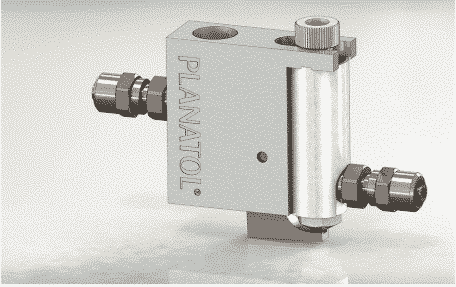

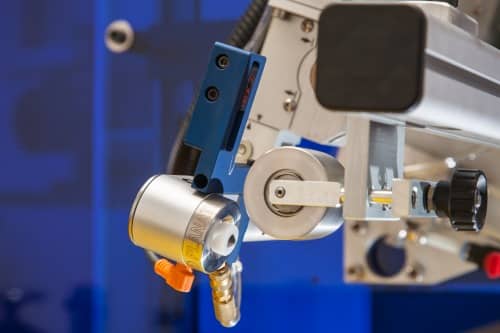

AKS 250 applicator head

The AKS 250 from Planatol is used for the non-contact application of dots and lines. It has a slim and compact design and features an on-board flash button. Easy to cleaning due to non-stick coating.

Optional: Product monitoring, heatable